地震地质 ›› 2025, Vol. 47 ›› Issue (1): 150-166.DOI: 10.3969/j.issn.0253-4967.2025.01.010

收稿日期:2024-05-13

修回日期:2024-08-26

出版日期:2025-02-20

发布日期:2025-04-09

通讯作者:

党嘉祥

作者简介:崔娅琪, 女, 2001年生, 现为中国地震局地质研究所构造地质学在读博士研究生, 研究方向为岩石流变学, E-mail: 1131687016@qq.com。

基金资助:

CUI Ya-qi( ), DANG Jia-xiang*(

), DANG Jia-xiang*( ), ZHOU Yong-sheng

), ZHOU Yong-sheng

Received:2024-05-13

Revised:2024-08-26

Online:2025-02-20

Published:2025-04-09

Contact:

DANG Jia-xiang

摘要:

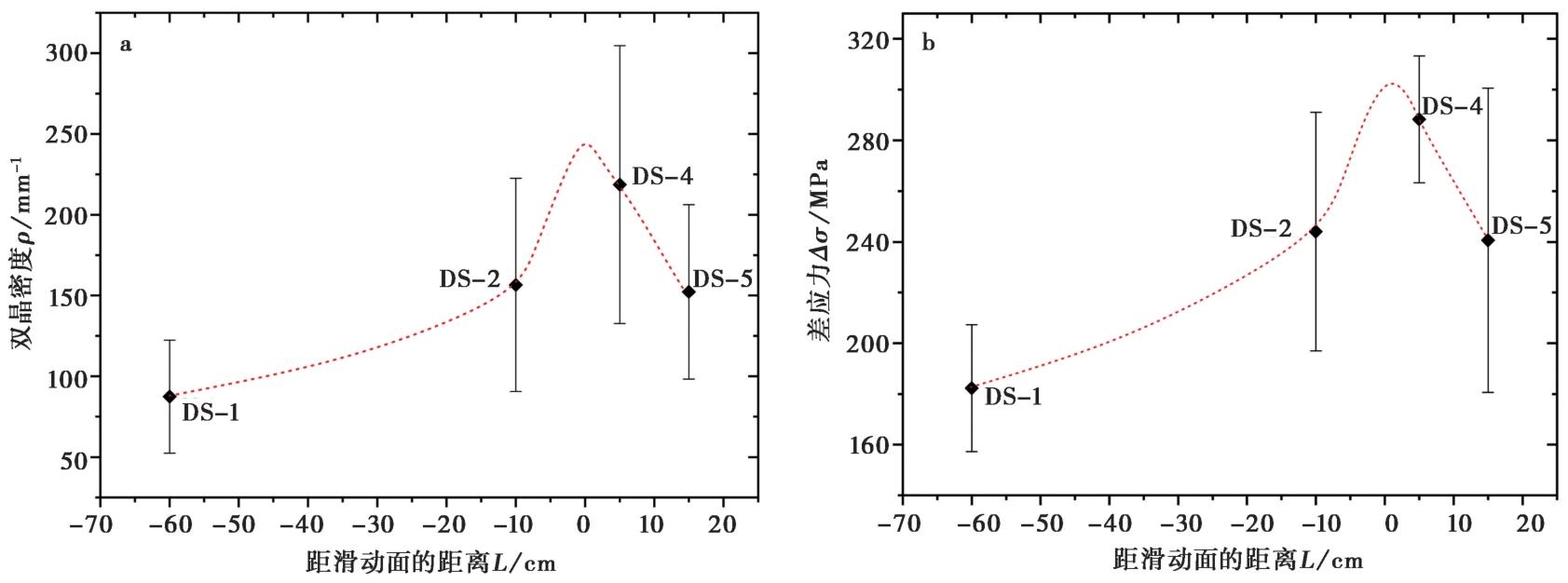

摩擦系数作为断层滑动的重要参数, 对断层稳定性和地震危险性评估具有指示意义, 摩擦系数的获取是断层研究的重要内容之一。文中通过统计龙门山断裂带地表断层岩中的方解石机械双晶密度, 估算了断层岩所承受的历史最大差应力, 进一步计算了断层的滑动摩擦系数。统计结果显示, 断层岩中的方解石双晶密度随着与滑动面距离的减小呈现明显的升高趋势, 在破碎带内为(87.39±35)mm-1, 在滑动面附近为(218.63±36)mm-1, 计算得到的差应力分别为(182.28±25)MPa和(288.30±25)MPa, 该特征表明断层滑动面附近持续承受差应力。用于双晶统计的样品采集于灰岩质断层岩中, 以往的地质调查资料显示这些断层岩的历史最大埋深约为5km。综合上述深度和差应力值, 以及前人对该区域构造应力的研究结果, 计算得到龙门山断裂带在水平和逆冲滑动时的稳态摩擦系数分别为0.61和0.13。上述计算采用的应力值为断层岩所承受的历史最大应力, 因而给出的摩擦系数为稳态滑动摩擦系数的上限。该结果与实验观察结果及科学钻探研究结果一致, 表明通过机械双晶估算断层稳态摩擦系数的方法具有可行性。

崔娅琪, 党嘉祥, 周永胜. 龙门山断层带内方解石机械双晶研究及对断层摩擦系数启示[J]. 地震地质, 2025, 47(1): 150-166.

CUI Ya-qi, DANG Jia-xiang, ZHOU Yong-sheng. MECHANICAL TWINNING OF CALCITE IN THE LONGMENSHAN FAULT ZONE AND ITS IMPLICATIONS FOR FAULT FRICTION COEFFICIENT[J]. SEISMOLOGY AND GEOLOGY, 2025, 47(1): 150-166.

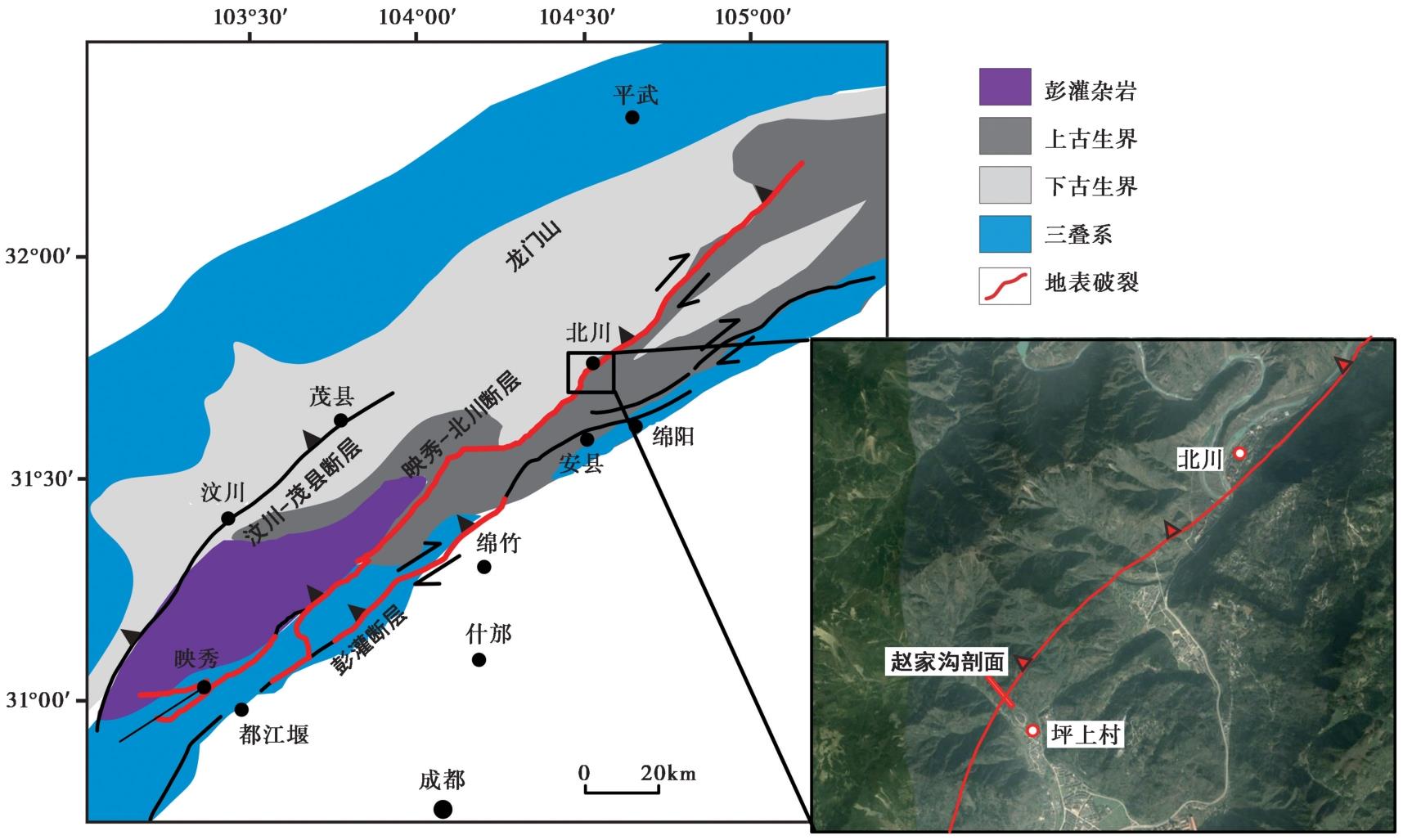

图1 龙门山断层区域地质图与赵家沟剖面的位置图(修改自Dang et al., 2021)

Fig. 1 Regional geological map of Longmenshan Fault and location map of Zhaojiagou outcrop(Dang et al., 2021).

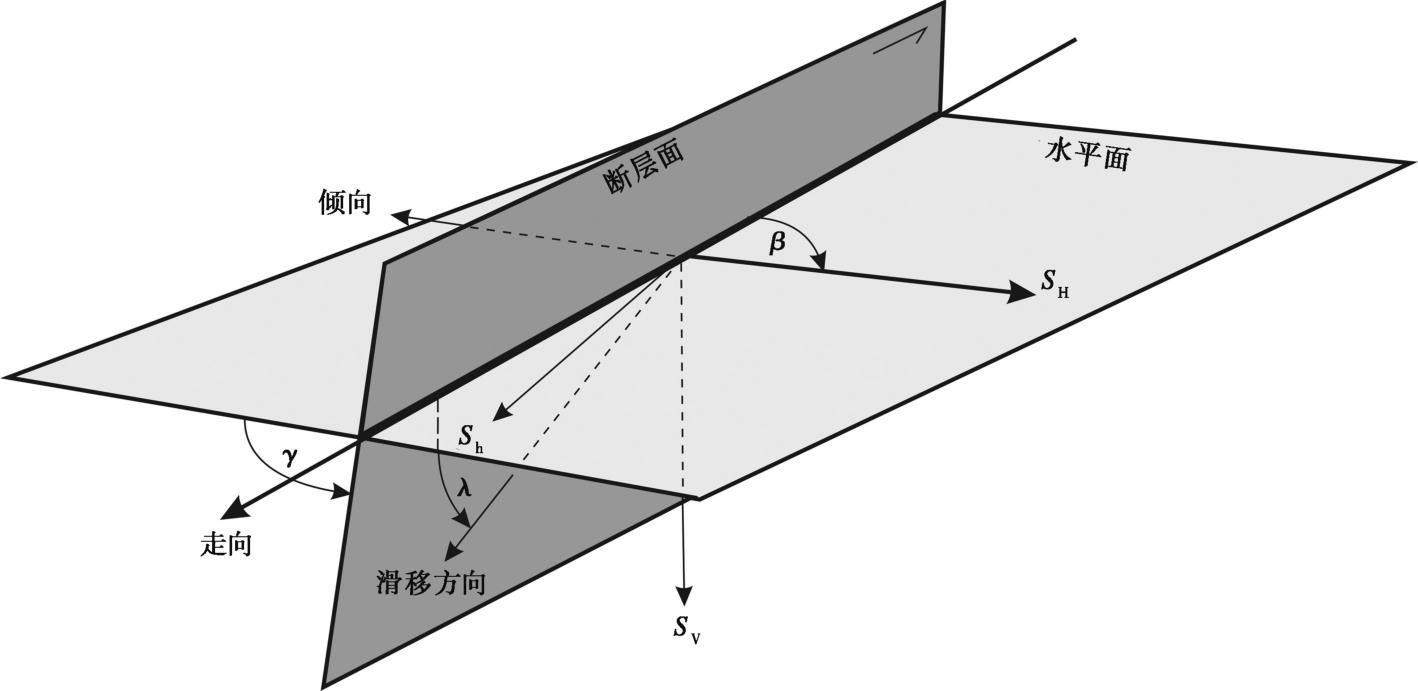

图3 断层受力模型图(Rybacki et al., 2011) SH最大水平应力; Sh最小水平应力; SV上覆岩层应力; λ 断层滑动角; γ 断层倾角; β 断层走向与SH的锐夹角

Fig. 3 Stress model diagram of fault(Rybacki et al., 2011).

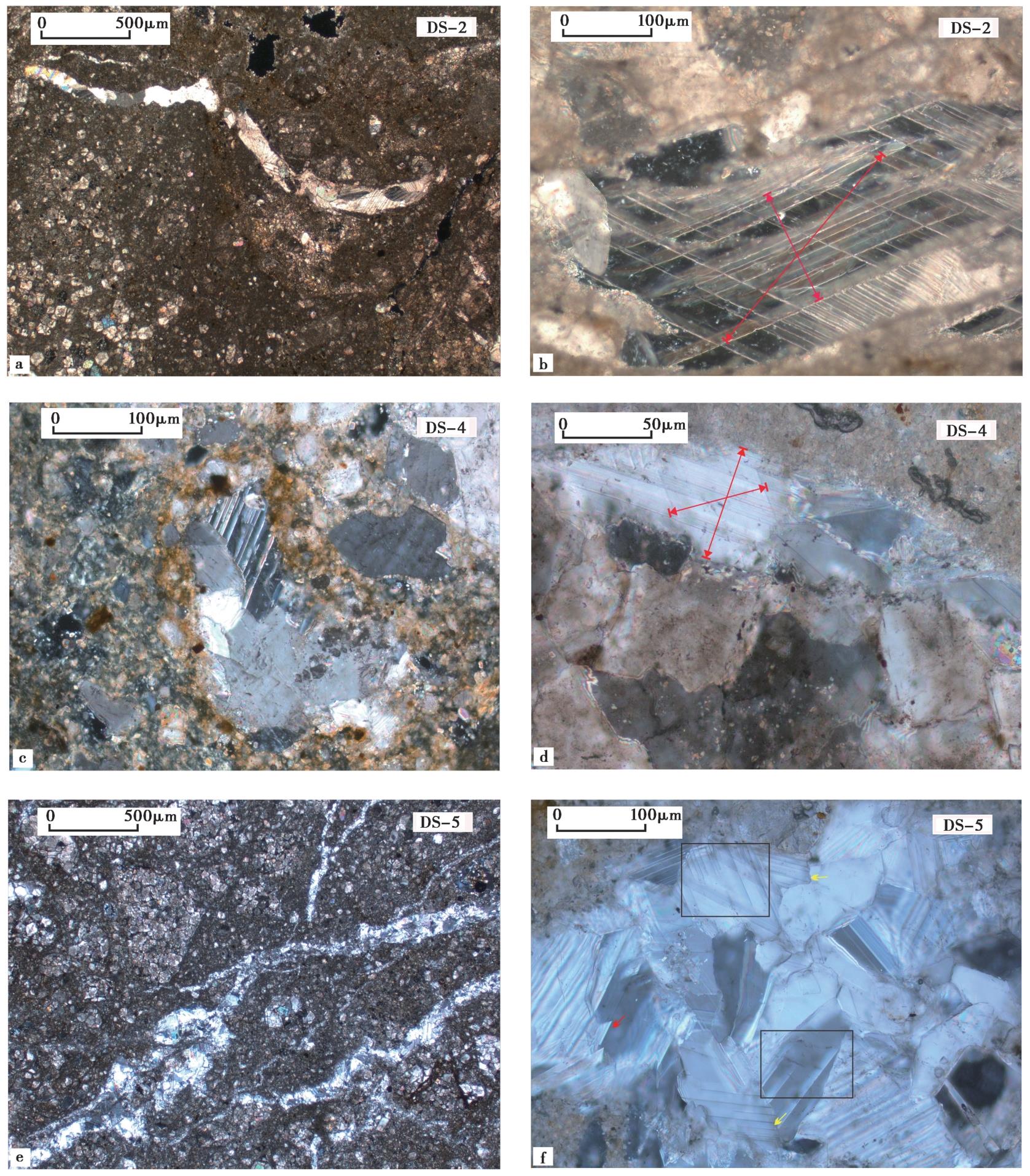

图5 断层核内的方解石脉和双晶微观图(临近滑动带样品) 带箭头的线段指示同一颗粒内展布的2组不同方向的双晶; 红色箭头指示双晶的楔形端部, 黄色箭头指示台阶状边缘, 黑色方框为双晶纹未贯穿的双晶颗粒

Fig. 5 Microscopic map of calcite veins and twinning in fault core(sample near the sliding zone).

| 样品 | 双晶密度/mm-1 | 平均双晶密度/mm-1 | 差应力/MPa |

|---|---|---|---|

| DS-1 | 125.156 | 87.39±35 | 182.28±25 |

| 68.212 | |||

| 52.438 | |||

| 68.923 | |||

| 64.851 | |||

| 70.247 | |||

| 85.249 | |||

| 93.196 | |||

| 67.218 | |||

| 81.337 | |||

| 130.039 | |||

| 72.122 | |||

| 100.313 | |||

| 87.655 | |||

| 74.914 | |||

| 156.512 | |||

| DS-2 | 78.186 | 156.60±66 | 244.01±47 |

| 60.643 | |||

| 69.881 | |||

| 89.286 | |||

| 141.326 | |||

| 80.221 | |||

| 211.416 | |||

| 162.966 | |||

| 144.849 | |||

| 208.656 | |||

| 183.415 | |||

| 387.584 | |||

| 207.809 | |||

| 137.497 | |||

| 164.331 | |||

| 62.181 | |||

| 168.646 | |||

| 125.896 | |||

| 128.874 | |||

| 123.154 | |||

| 114.661 | |||

| DS-2 | 165.837 | 156.60±66 | 244.01±47 |

| 238.542 | |||

| 274.369 | |||

| 138.648 | |||

| 185.529 | |||

| 173.913 | |||

| DS-4 | 207.970 | 218.63±86 | 288.30±25 |

| 182.815 | |||

| 204.167 | |||

| 204.918 | |||

| 293.255 | |||

| DS-5 | 128.103 | 152.26±54 | 240.60±60 |

| 218.818 | |||

| 162.317 | |||

| 202.533 | |||

| 189.673 | |||

| 98.328 | |||

| 109.518 | |||

| 108.814 |

表1 分析样品双晶密度与所受差应力统计计算结果

Table1 The statistical results of twin density and differential stress were analyzed

| 样品 | 双晶密度/mm-1 | 平均双晶密度/mm-1 | 差应力/MPa |

|---|---|---|---|

| DS-1 | 125.156 | 87.39±35 | 182.28±25 |

| 68.212 | |||

| 52.438 | |||

| 68.923 | |||

| 64.851 | |||

| 70.247 | |||

| 85.249 | |||

| 93.196 | |||

| 67.218 | |||

| 81.337 | |||

| 130.039 | |||

| 72.122 | |||

| 100.313 | |||

| 87.655 | |||

| 74.914 | |||

| 156.512 | |||

| DS-2 | 78.186 | 156.60±66 | 244.01±47 |

| 60.643 | |||

| 69.881 | |||

| 89.286 | |||

| 141.326 | |||

| 80.221 | |||

| 211.416 | |||

| 162.966 | |||

| 144.849 | |||

| 208.656 | |||

| 183.415 | |||

| 387.584 | |||

| 207.809 | |||

| 137.497 | |||

| 164.331 | |||

| 62.181 | |||

| 168.646 | |||

| 125.896 | |||

| 128.874 | |||

| 123.154 | |||

| 114.661 | |||

| DS-2 | 165.837 | 156.60±66 | 244.01±47 |

| 238.542 | |||

| 274.369 | |||

| 138.648 | |||

| 185.529 | |||

| 173.913 | |||

| DS-4 | 207.970 | 218.63±86 | 288.30±25 |

| 182.815 | |||

| 204.167 | |||

| 204.918 | |||

| 293.255 | |||

| DS-5 | 128.103 | 152.26±54 | 240.60±60 |

| 218.818 | |||

| 162.317 | |||

| 202.533 | |||

| 189.673 | |||

| 98.328 | |||

| 109.518 | |||

| 108.814 |

图6 断层带不同位置双晶密度值及差应力值分布图 横坐标零点指示断层滑动带中心, 负值为断层上盘, 正值为断层下盘

Fig. 6 Distribution of twins density and differential stress at different positions of fault zone.

| [1] |

陈洪德, 刘磊, 林良彪, 等. 2021. 川西坳陷西部龙门山隆升时期上三叠统须家河组沉积响应[J]. 石油与天然气地质, 42(4): 801—815.

|

|

|

|

| [2] |

付碧宏, 王萍, 孔屏, 等. 2008. 四川汶川5.12大地震同震滑动断层泥的发现及构造意义[J]. 岩石学报, 24(10): 2237—2243.

|

|

|

|

| [3] |

官云彬, 徐琳, 陈永东, 等. 2023. 龙门山前山断裂中段古地震研究[J]. 四川地震, (1): 18—25.

|

|

|

|

| [4] |

韩亮, 周永胜, 陈建业, 等. 2010. 汶川地震基岩同震断层泥结构特征[J]. 第四纪研究, 30(4): 745—758.

|

|

|

|

| [5] |

李本亮, 雷永良, 陈竹新, 等. 2011. 环青藏高原盆山体系东段新构造变形特征: 以川西为例[J]. 岩石学报, 27(3): 636—644.

|

|

|

|

| [6] |

李海兵, 王宗秀, 付小方, 等. 2008. 2008年5月12日汶川地震(MS8.0)地表破裂带的分布特征[J]. 中国地质, 35(5): 803—813.

|

|

|

|

| [7] |

李勇, 黄润秋, 周荣军, 等. 2009. 龙门山地震带的地质背景与汶川地震的地表破裂[J]. 工程地质学报, 17(1): 56—71.

|

|

|

|

| [8] |

木红旭. 2020. 川西晚三叠世前陆盆地的形成与演化[D]. 北京: 中国地质大学.

|

|

|

|

| [9] |

冉勇康, 陈立春, 陈桂华, 等. 2008. 汶川 MS8.0 地震发震断裂大地震原地重复现象初析[J]. 地震地质, 30(3): 630—643.

|

|

|

|

| [10] |

王萍, 付碧宏, 张斌, 等. 2009. 汶川8.0级地震地表破裂带与岩性关系[J]. 地球物理学报, 52(1): 131—139.

|

|

|

|

| [11] |

徐锡伟, 闻学泽, 叶建青, 等. 2008. 汶川 MS8.0 地震地表破裂带及其发震构造[J]. 地震地质, 30(3): 597—629.

|

|

|

|

| [12] |

张培震, 徐锡伟, 闻学泽, 等. 2008. 2008年汶川8.0级地震发震断裂的滑动速率、 复发周期和构造成因[J]. 地球物理学报, 51(4): 1066—1073.

|

|

|

|

| [13] |

郑剑, 单业华. 2020. 方解石e-双晶的古应力分析: 原理和展望[J]. 大地构造与成矿学, 44(1): 47—56.

|

|

|

|

| [14] |

周永胜, 韩亮, 靖晨, 等. 2014. 龙门山断层脆-塑性转化带流变结构与汶川地震孕震机制[J]. 地震地质, 36(3): 882—895. doi: 10.3969/j.issn.0253-4967.2014.03.025.

|

|

|

|

| [15] |

周永胜, 何昌荣. 2009. 汶川地震区的流变结构与发震高角度逆断层滑动的力学条件[J]. 地球物理学报, 52(2): 474—484.

|

|

|

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

De Bresser J H P. 1996. Steady state dislocation densities in experimentally deformed calcite materials: Single crystals versus polycrystals[J]. Journal of Geophysical Research, 101(B10): 22189—22201.

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [1] | 花春雨, 石峰, 魏占玉. 龙门山断裂带映秀-北川断裂白沙河段滑动速率[J]. 地震地质, 2024, 46(6): 1295-1313. |

| [2] | 呼楠, 龙锋, 王莹, 徐良鑫. 龙门山断裂带北东段现今地震活动特征[J]. 地震地质, 2024, 46(4): 856-875. |

| [3] | 郭祥云, 房立华, 韩立波, 李振月, 李春来, 苏珊. 川滇菱形块体东边界震源机制与应力场特征[J]. 地震地质, 2024, 46(2): 371-396. |

| [4] | 徐志萍, 刘巧霞, 刘志, 田晓峰, 王夫运, 段永红, 林吉焱, 邱勇, 唐淋. 芦山强震区上地壳速度和泊松比分布特征及其动力学意义[J]. 地震地质, 2023, 45(6): 1400-1418. |

| [5] | 宋冬梅, 王慧, 单新建, 王斌, 崔建勇. 基于汶川地震前重力场与热场关联性分析的应力致热假说的野外证明[J]. 地震地质, 2023, 45(5): 1112-1128. |

| [6] | 叶轶佳, 谭锡斌, 钱黎. 通过河流剪切力获取河道侵蚀速率和基岩可蚀系数——以龙门山为例[J]. 地震地质, 2022, 44(1): 115-129. |

| [7] | 郭树松, 祝意青, 徐云马, 刘芳, 赵云峰, 张国庆, 朱辉. 汶川地震前失稳过程的重力场观测证据[J]. 地震地质, 2021, 43(6): 1368-1380. |

| [8] | 汤井田, 杨磊, 任政勇, 胡双贵, 徐志敏. 龙门山断裂带卫星重力场特征及其发震机制[J]. 地震地质, 2019, 41(5): 1136-1154. |

| [9] | 李振月, 万永革, 盛书中. 米亚罗断裂活动与汶川地震序列活动的关系[J]. 地震地质, 2019, 41(1): 72-83. |

| [10] | 江敏, 陈九辉, Yasuto Kuwahara, Reiken Matsushita. 利用小震震源机制解研究汶川地震后龙门山断裂带中段应力场时空演化[J]. 地震地质, 2018, 40(2): 310-322. |

| [11] | 刘洋, 何昌荣. 龙门山断层带浅钻花岗岩中断层泥的摩擦本构参数[J]. 地震地质, 2017, 39(5): 917-933. |

| [12] | 万永魁, 刘峡, 沈军, 王雷, 李妍. 汶川地震前龙门山及其周缘断裂形变运动与应力累积的数值模拟[J]. 地震地质, 2017, 39(4): 853-868. |

| [13] | 王旭光, 李传友, 吕丽星, 董金元. 龙门山后山断裂中段汶川-茂县断裂的晚第四纪活动性分析[J]. 地震地质, 2017, 39(3): 572-586. |

| [14] | 梁明剑, 陈立春, 冉勇康, 王虎, 李东雨. 龙门山断裂南段天全段的新活动特征与1327年天全地震的关系[J]. 地震地质, 2016, 38(3): 546-559. |

| [15] | 苏鹏, 田勤俭, 梁朋, 李文巧, 王林. 基于青衣江变形河流阶地研究龙门山断裂带南段的构造活动性[J]. 地震地质, 2016, 38(3): 523-545. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||